Case Study: Offshore Sand Management

SoliDetect 1.0 Implementation for Solids Management - Field Trial

The customer needed a sensor system for accurate solids monitoring, and the ROCSOLE SoliDetect 1.0 profiler was installed in a separator vessel, demonstrating the effectiveness of SoliDetect 1.0 Implementation in providing precise measurement capabilities in challenging conditions.

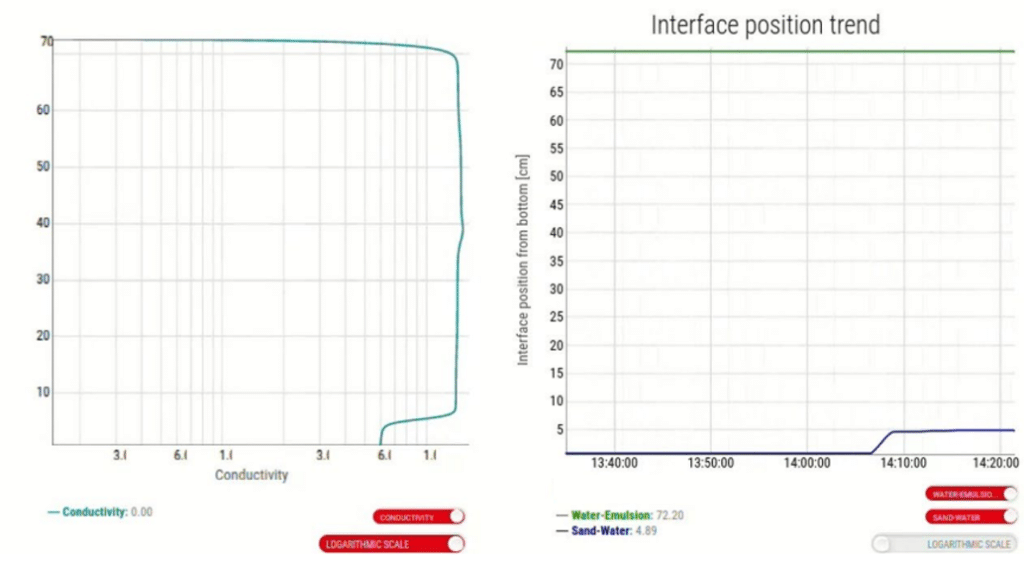

The system accurately measured and reported solids build-up, with a high degree of correlation between ROCSOLE SoliDetect 1.0 and actual solids deposited.

This enabled the customer to monitor solids build-up effectively and track the performance of the automated cleaning system.

Sand Management: Existing Solutions Are Unreliable

The customer required a high-pressure sensor system for accurate solids monitoring, with a design pressure of 345 barg. Factory acceptance tests have confirmed its precise measurement capabilities at this operating pressure.

Challenge

Operating at high pressure poses technical and operational challenges and this limits the methods available for accurate solids measurement.

It is essential to accurately measure the solids build-up to maximize the equipment’s operating time and reduce shutdowns.

Solution

ROCSOLE SoliDetect 1.0 profiler was installed in high-pressure vessel and can accurately measure and report solids build-up.

The customer’s comparison of ROCSOLE SoliDetect 1.0 vs. actual solids deposited showed a high degree of correlation.

Meet the team to tackle the challenge

All success is based on great teamwork and in this case we’d like to thank our client's team for the great cooperation. Please meet the Rocsole team involved:

ROCSOLE SoliDetect 1.0 Profiler offers a comprehensive approach to high-pressure solids management, providing real-time insights and proactive maintenance capabilities.

Results

The data provided by SoliDetect 1.0 enables the customer to accurately monitor and measure the solids build-up and also allows tracking the effectiveness of the automated cleaning system.

Before

This test result demonstrated that the system could detect even very small amounts of solids at the bottom of the vessel.

The Details in Overview

System Design:

- Operating Temperature 85 °C

- Design Pressure 345 barg

- Design Temperature 115 °C

- 1 x 32 Electrode sensor

- User Interface webroc 1.0

Delivery Content:

The installed package contained the Rocsole sand management system SoliDetect 1.0

- 32 electrodes of measurement area 720 mm

- IECEx certified

- Sensor material EN 1.4462 Duplex steel

- Cabinet material Aluminum Epoxy Coated

- Vessel bottom installation