PRODUCTS

Multi-Layer Liquid Processes Insights

by Award-Winning Finnish Innovator Rocsole

Four areas most operation managers are concerned about:

Unreliable processing can cause:

Lower Product Quality

- Unable to maintain export oil specifications.

- Lack of control of oil-in-water, environmental impact and significant financial loss.

Prevention is possible through level detection and monitoring within the vessels.

Reduced Production Performance

- Shut-in wells.

- Reduced operating capacity/ throughput.

- Lack of clarity on the performance of your Enhanced Oil Recovery techniques.

Understanding the separation process can optimise and increase production.

Rising Chemical Expenditure

The uncertainty of what is happening inside vessels can cause redundant or additional chemical injection.

Unnecessary Maintenance Costs

Excess export water causes corrosion in equipment, pipelines and refineries. This can lead to extensive repair or maintenance, and financial penalties. Lack of data and insights cause unplanned shutdowns and run to failures.

Unplanned shutdowns, reduced uptime and bottlenecks should not be accepted - enhance your insights with our help.

The current solutions lack reliable insights and data, this prevents the operators from relying on the information and thus taking timely actions. Operation teams need relevant data to improve performance and take corrective measures.

You deserve a better tool that keeps you well-informed 24/7.

Don’t accept the status quo. Get truly reliable insights.

Data starvation is history. Take the next step with patented deeptech solutions for better product quality and actions for decarbonization.

Get your processing to the next level with SeeBeyond

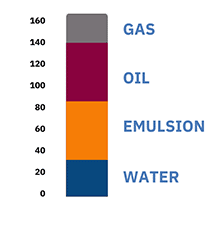

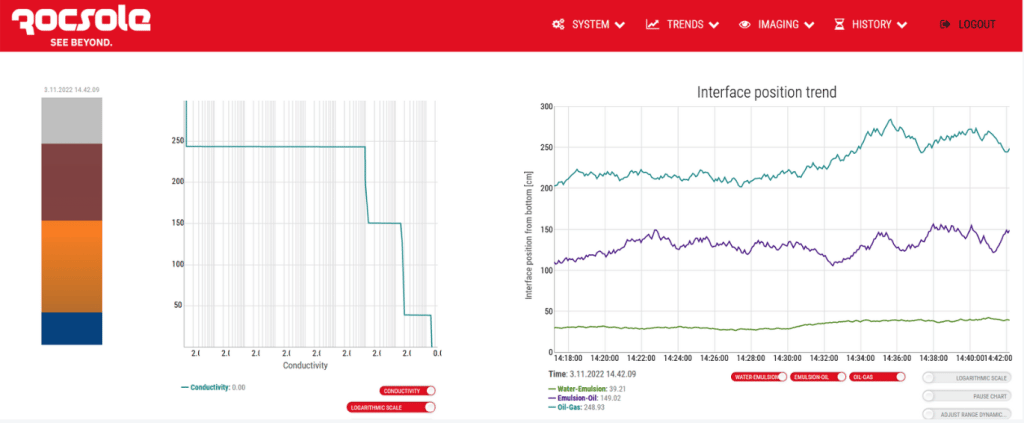

Electrical Tomography provides a real-time permittivity/conductivity profile which generates an overall picture of the actual process levels. With the SeeBeyond you can reliably identify when the changes happen. The interpretation is based on unique actual real-time data.

Our Electrical Tomography technology is proven robust working even with sensor surfaces being contaminated (fouling). The technology enables the measurements of interface levels for Water, Emulsion, Oil, Gas and even Foam - 24/7 updated for your information and monitoring, with more than 1,000 times more data points per day than other incumbent solutions.

LiquiDetect 2.0 User Interface

See how it works

Your Operational Success Unleashed

Do not accept lack of data in your operations any longer.

Clever Thought through Data Integration

Our data intelligence software is designed to integrate with your systems. Rocsole LiquiDetect 2.0 collects "real-time" process data and is available in multiple formats upon request using our interactive reporting software.

Use Reliable Insights for Improved Decision-Making

The Rocsole LiquiDetect 2.0 system provides you with rapid and reliable data that allows you to understand and manage your process's water, emulsion, oil, and gas interfaces through precise level detection. Now you can be proactive rather than reactive.

Effectively Avoid Unnecessary Risks and Cost

Understanding what is happening inside your vessels can prevent the export of excess water, reduce corrosion, and avoid possible environmental hazards due to high oil-in-water.

Maximize Production & Revenues

Maximise your process capacity by improving the control of separation inside vessels. Improve throughput and product quality. Reduce the frequency of unplanned shutdowns and plant trips. Enable proactive decision makings and planning, ultimately delivering higher overall production performance.

Download LiquiDetect 2.0 Tech Specs

Shape the future of your operation with a reliable and robust patented award-winning level detection solution.

Don’t let the vessel walls restrict your performance.

Brought to you by Rocsole, your partner for

next-level operational excellence in the Oil & Gas industry.

Check out our patents

Electrical tomography for vertical profiling

6 Sep, 2017

Concept and method for tank scanning (vertical profiling and interface detection)

Determining an electrical property of interest of materials in a target domain

26 May, 2016

Deposition estimation with a pig sensor – method for compensating the effects of unknown sensor position.

Method for determining a quantity of interest in a target domain, apparatus and computer program

9 Jan, 2015

Method for estimating deposits using an approximation error method

We are happy to help configure the solution setup that is perfect for your operation.

Let’s talk: