PRODUCTS

Sand Management Solutions

by Award-Winning Finnish Innovator Rocsole

Four areas most operation managers are concerned about:

Sand accumulation in processes can cause...

Reduced Throughput

Undetected solid buildup in pipelines and process vessels reduces the operating capacity.

Reduced Production Performance

Solids movement can cause damage to infrastructure such as pipeline, pumps, valves, etc.; increase the potentials for corrosion.

Expensive Downtimes

Blockages inside pipelines and process vessels may lead to expensive unplanned shutdowns.

Unnecessary Safety Risks

Corrosion & erosion of pipelines may lead to leakage of process fluids.

Unplanned shutdowns and maintenance can be made a distant memory.

The current solutions lack reliable insights and data; this prevents the operators from relying on the information and thus taking timely actions. Operation teams need relevant data to improve performance and take corrective measures.

You deserve a better tool that keeps you well-informed 24/7.

Remove your processing uncertainty.

Shape the future of your operation with a reliable and robust patented award-winning solution.

Get your processing to the next level with SeeBeyond

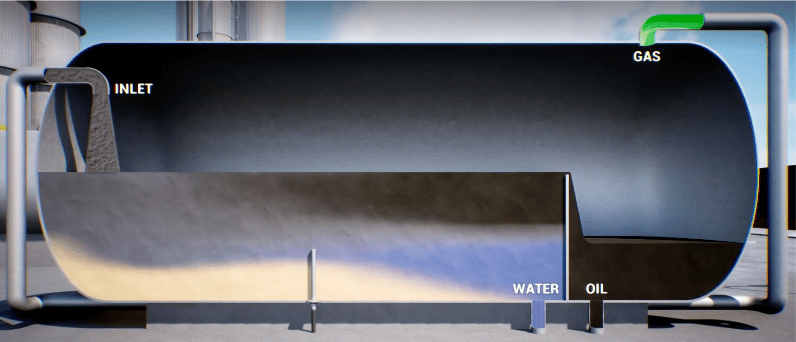

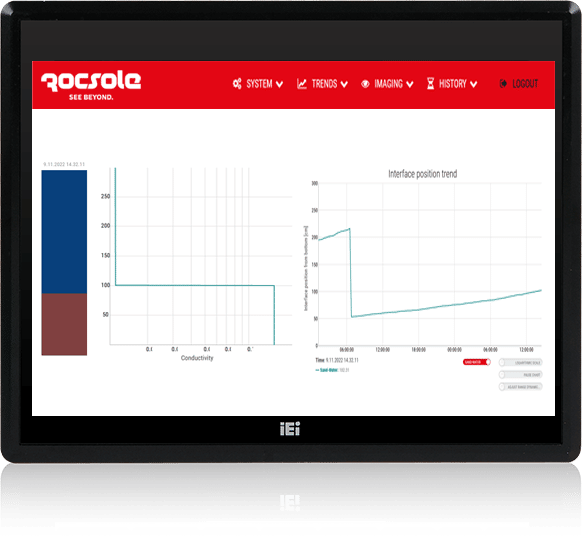

Our electrical tomography-based SeeBeyond technology provides a real-time permittivity /conductivity profile, generating an overall picture of what is happening inside for typically data starved operating environments.

The interpretation is based on actual real-time data. Now you can SeeBeyond the walls of vessels or pipelines and identify when changes happen.

Our Electrical Tomography technology is robust and reliable as it can operate despite contamination (fouling). The technology enables the measurements of interface levels for solids buildup and liquids - 24/7 updated for your information and monitoring.

See how it works

Your Operational Success Unleashed

Do not accept sand contamination in your operations any longer.

Informed Decisions through Data Integration

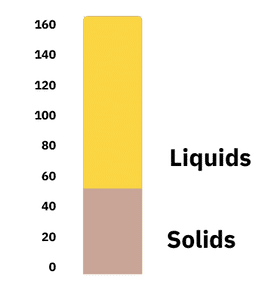

Our data intelligence software is designed to integrate with your systems. Rocsole SoliDetect 1.0 collects "real-time" process data and is available in multiple formats upon request using our interactive reporting software.

Use Reliable Insights for Improved Efficiency

The Rocsole SolidDetect 1.0 provides rapid and reliable data, allowing you to understand and manage solids buildup within your process. Allow you to be proactive rather than reactive.

Effectively Avoid Unnecessary Risks and Cost

Real-time data of solids buildup from within the process vessels prevents unexpected shutdowns or asset deterioration. Relevant data improves overall performance, increases throughput and reduces cost. No more environmental hazards, and it helps you reduce carbon emissions.

Maximize Production & Revenues

The detailed, real-time information provided will not only help you with avoiding unnecessary damage but also can help you optimise production. Where this approach has been implemented, our clients were able to make changes to individual wells, increasing oil production and identifying those areas where sand production is not an issue.

Don’t let the vessel walls restrict your performance.

Brought to you by Rocsole, your partner for

next-level operational excellence in the Oil & Gas industry.

Check out our patents

Electrical tomography for vertical profiling

6 Sep, 2017

Concept and method for tank scanning (vertical profiling and interface detection)

Determining an electrical property of interest of materials in a target domain

26 May, 2016

Deposition estimation with a pig sensor – method for compensating the effects of unknown sensor position.

Method for determining a quantity of interest in a target domain, apparatus and computer program

9 Jan, 2015

Method for estimating deposits using an approximation error method

We are happy to help configure the solution setup that is perfect for your operation.

Let’s talk: