Case Study: Offshore INSTALLATION

Offshore Emulsion Watch Using LiquiDetect 2.0

The customer required a reliable solution for its offshore field to ensure precise monitoring of emulsion levels, manage water levels accurately, and gain comprehensive insights into the operational performance.

ROCSOLE LiquiDetect 2.0 product was applied, and it has successfully measured and recorded the layers of oil, emulsion, and water inside the separator vessel.

Challenge

The customer required a reliable solution to ensure precise monitoring of emulsion levels, manage water levels accurately and gain comprehensive insights into the operational performance. Previously, the customer has tried to achieve this goal by utilizing two other options, including a nucleonic system.

Solution

ROCSOLE proposed its unique Electrical Tomography based solution with a bespoke design which included a customized sensor, to manage the space constraints. This design allowed full profiling of the vessel and easy installation.

Meet the team to tackle the challenge

All success is based on great teamwork and in this case we’d like to thank our client's team for the great cooperation. Please meet the Rocsole team involved:

ROCSOLE LiquiDetect 2.0 Profiler offers a reliable solution for precise liquid level management in challenging offshore environments, enhancing operational efficiency and productivity.

Results

LiquiDetect 2.0 has successfully measured and recorded the layers of oil, emulsion, and water inside the separator vessel. In addition, the results enabled the customer to see the impact of solids within the oil layer.

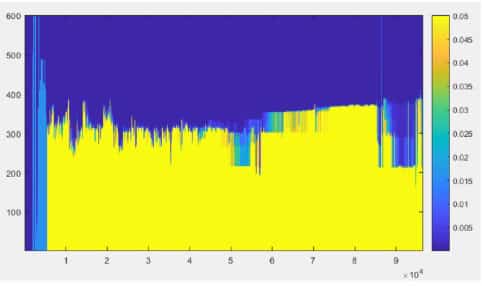

Picture

Visualization of profiles during 2.5 months after commissioning.

The Details in Overview

System Design:

- Operating Pressure 9 barg

- Design Pressure 25 barg

- System Operating Temperature -75 °C to +95 °C

- Design Temperature -29 °C (-20 °F) to +100° C (200 °F)

- 1 x 64 Electrode sensor

- User Interface Webroc 1.0

Delivery Content:

The installed package contained the Rocsole’s

award-winning LiquiDetect 2.0 solution

- 64 electrodes of measurement area 2880 mm

- CSA certified

- Sensor material EN 1.4410 (Super Duplex)

- Cabinet material EN 1.4404

- Vessel top installation via existing nozzle