Dynamic Thresholding Technology for Smarter Separation Vessel Monitoring

By: Marzieh Hosseini, Technology Manager, Rocsole

In the oil and gas industry, extracting impure oil or water from separation vessels can lead to significant additional processing costs. At Rocsole, our mission is to help operators “SeeBeyond” by delivering accurate, real-time information on the processes happening inside separation vessels.

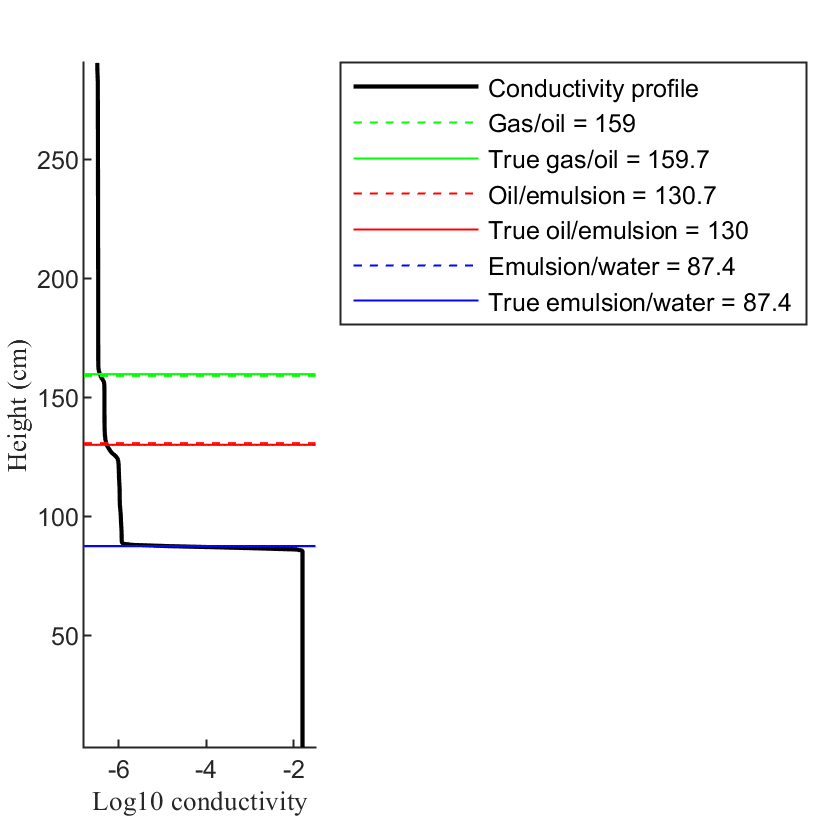

Our LiquiDetect and SoliDetect profilers are designed to provide detailed information about the interface levels of oil, emulsion, water, and sand. These profilers use electrodes to collect raw data, which is then processed using advanced process tomography to generate vertical conductivity profiles. As each material inside the vessel has a distinct conductivity range, we can identify the interfaces between them by applying threshold values to the computed conductivity profiles.

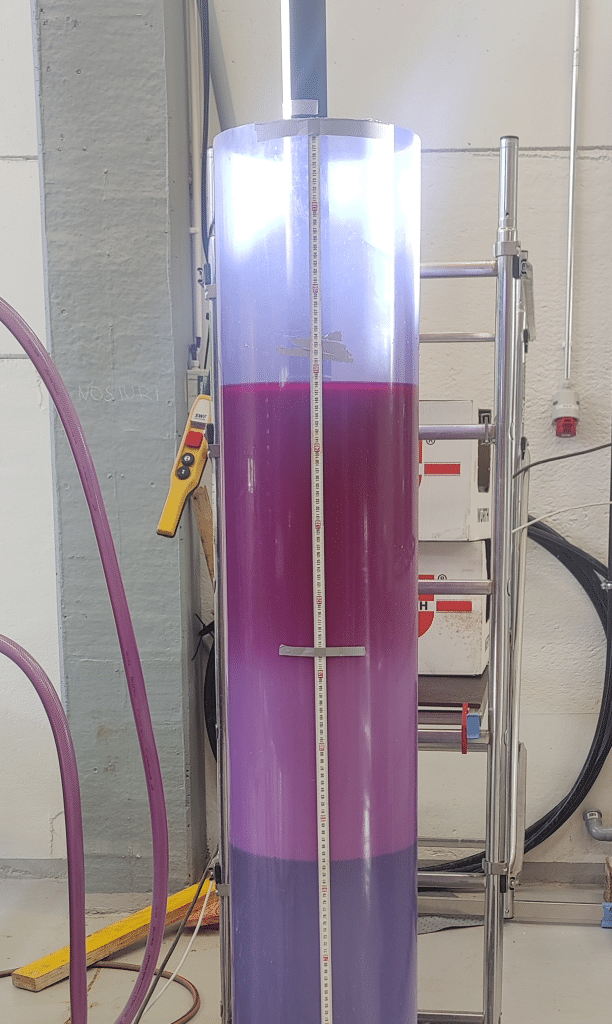

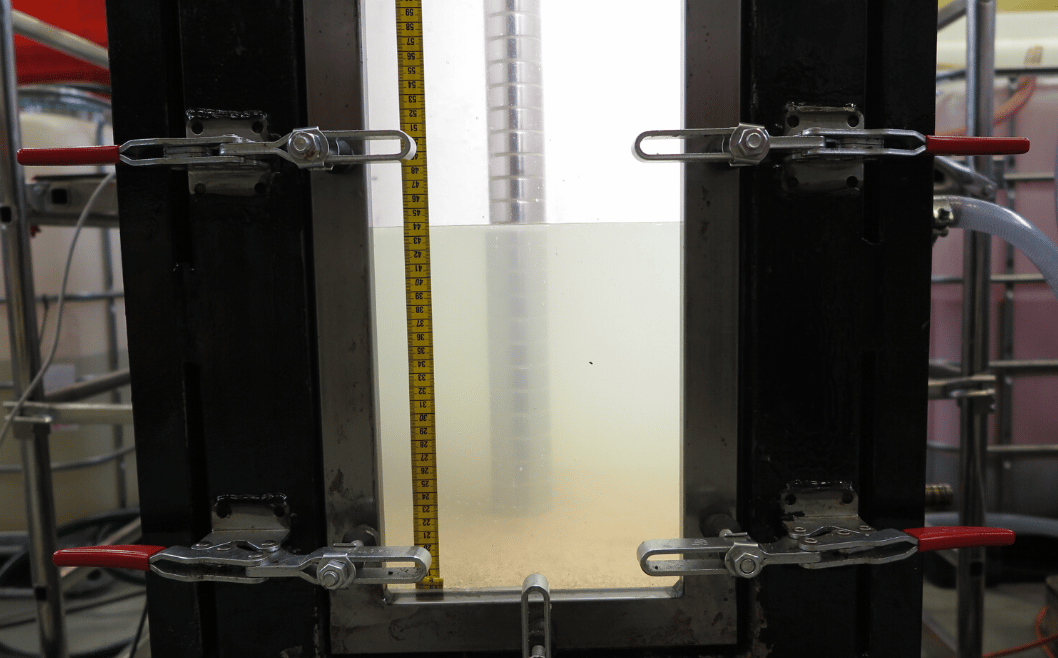

The images below illustrate this principle in action. The first image shows a separation vessel filled with four distinct layers: water at the bottom, followed by emulsion, oil, and air at the top. The second image presents the computed conductivity profile from a similar case, where each material interface is marked by characteristic changes in conductivity. The black line represents the overall conductivity profile, while dashed and solid coloured lines indicate both computed and actual interfaces between gas/oil, oil/emulsion, and emulsion/water layers. This visualisation demonstrates how conductivity thresholds can be used to accurately detect these interfaces.

However, in dynamic environments, particularly in well-testing applications where the physical properties of oil and water fluctuate, fixed and static thresholds often may not be sufficient, or may require several adjustments. To overcome this limitation, we have developed a dynamic thresholding feature that enables the system to automatically adapt to changing liquid properties in real time.

This feature not only enhances the accuracy of the interface computations but also simplifies the calibration process. Operators can now install profilers without requiring manual calibration by field service agents, reducing setup time and operational overhead.

The dynamic thresholding feature has been successfully implemented, and our ongoing efforts are focused on further improving its robustness and reliability. We believe the newly developed feature represents a significant step forward in advanced separation vessel monitoring.

We welcome collaboration with industry professionals to explore the operational variability of process liquids and to identify new opportunities for enhancing our measurement technologies.