Gaining Insights into Separation by Using SeeBeyond Technology

By: Prof. Johan Sjöblom, James Walls & Antti Nissinen

The key focus for Rocsole is to understand our customers’ headaches and to find the best solutions for their issues through the utilisation of Electrical Tomography. One key aspect is in the understanding of the separation processes in Oil and Gas.

The need for an efficient separation process is vital so as to meet export and environmental targets, typically an export requirement is that the export oil should contain less than 0,5 % water and the produced water contains less than 30 ppm oil. Excess water in the oil export will potentially lower the price of the oil exported and higher oil in water (pollution) levels can have a regulatory and social impact.

Separation problems

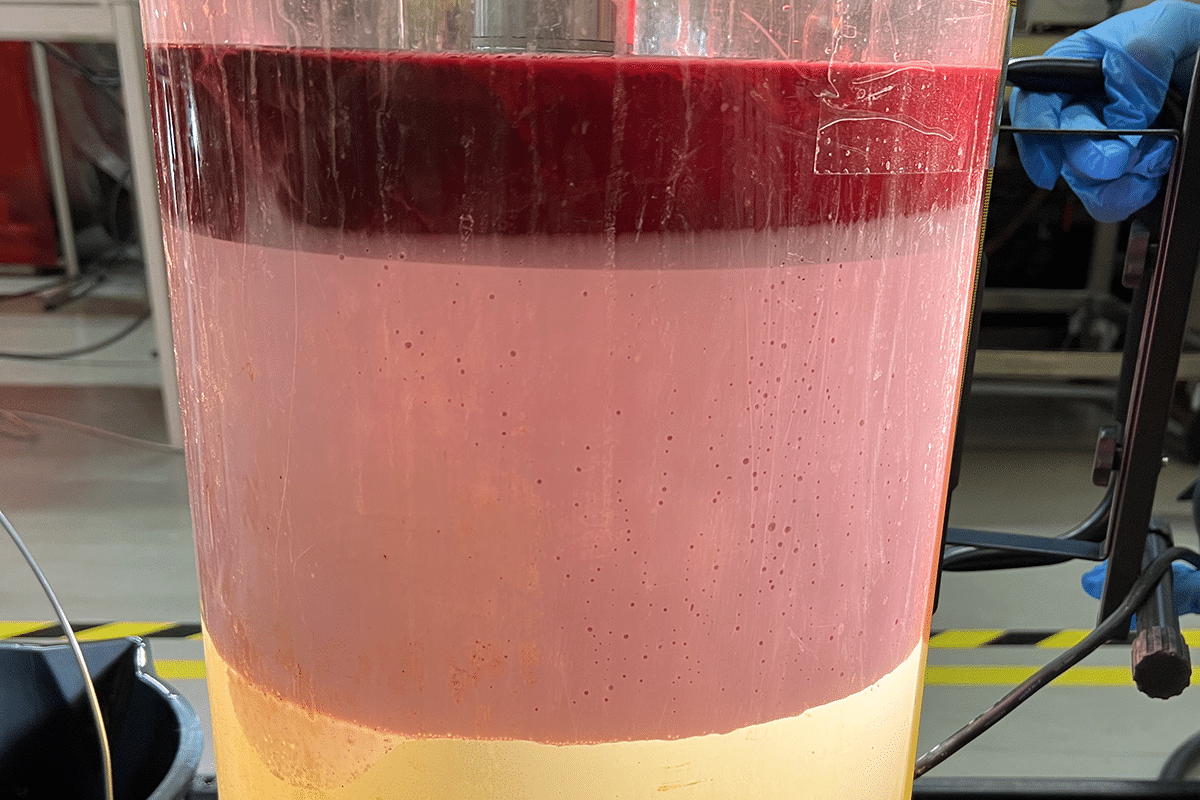

Normally the issues with the separation process occurs when there is the presence of water, oil and solids. When water and oil combine they form a water/oil emulsion which consists of droplets with different sizes (polydispersity). The system is unstable and the largest water droplets will merge (coalesce) and the water will separate as a different aqueous phase. Hence the fluids in the separator will have a water phase and an oil phase. The smaller droplets will need a longer time to coalesce and the oil quality will depend on the duration of this process.

Rocsole LiquiDetect

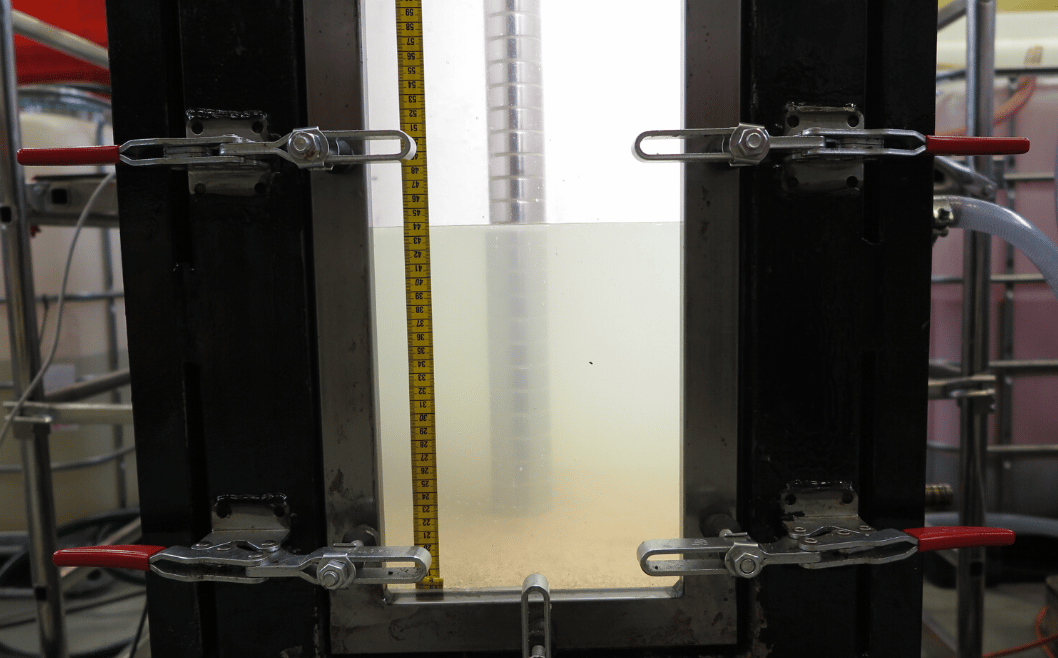

In order to follow the oil/water separation process Rocsole is uses the LiquiDetect system for liquid/liquid level detection. The LiquiDetect system contains a mechanical sensor, an electronic cabinet and an enclosure computer. The mechanical sensor is inserted into the operation process and gives up to 4 level interfaces as outputs. From the level interface information, we can determine the thickness of each layer. The information gathered is based on the permittivity of the oil phase and the conductivity contribution from the water phase and the emulsion contribution is seen in the conductivity measurement. The advantage with this information is that the separation process can be visualised and understood, this allows decision to be made on chemical dosing/treatment, well configurations and process settings.

Rocsole SoliDetect

Solids in separation process can originate from reservoirs so mainly they are sand (silica) and chalk (calcium carbonate), in addition solids/scale can be generated due to water incompatibility or process changes. Problems typically occur in the water phase and at the Interface layers, the impact depends on the particle size and composition of the solids.

Rocsole SoliDetect system can detect the presence and thickness of the solid build up within the vessels.

Benefits of the Rocsole sensor systems

The Rocsole LiquiDetect and SoliDetect systems provide customers an insight within separation vessels and allow real-time the information on the separation kinetics by measuring the liquid/liquid and solid boundaries. This information allows decisions to be made that can improve the efficiency of the whole process. The improvements can have an impact on energy consumption, shorten separation times and lower energy consumption.

The development of efficient separation operations will be an important tool in the decarbonisation process towards a greener community.